Why is My Car Not Starting?

There’s nothing more frustrating than getting into your car, turning the key (or pressing the start button), and having nothing happen. A car that won’t start can be a major inconvenience and can indicate various underlying issues. This comprehensive guide will help you understand the many potential causes and what you can do to diagnose and potentially fix the problem.

KC Car Products earns a commission from our sponsored links.

Common Causes for a Car Not Starting

Dead Battery: A dead or weak battery is the most frequent cause of a car not starting. It can result from leaving lights on, a faulty alternator, or simply an old battery that can no longer hold a charge. Symptoms include a clicking sound or complete silence when turning the key.

Faulty Starter Motor: The starter motor cranks the engine to initiate ignition. If it fails, the engine won’t turn over. Common signs include a clicking noise when you turn the key or no sound at all. Over time, the starter motor’s internal components can wear out, necessitating replacement.

Ignition System Issues: Problems within the ignition system, such as bad spark plugs or a failed ignition coil, can prevent the engine from starting. Symptoms include the engine cranking without starting, rough idling, or misfires. Regular maintenance of the ignition components can help avoid these issues.

Fuel System Problems: Issues like an empty fuel tank, clogged fuel filter, or faulty fuel pump can prevent fuel from reaching the engine. Symptoms include the engine cranking but not starting, sputtering, or stalling. Ensuring the fuel system is clean and the tank is adequately filled can prevent these problems.

Faulty Alternator: The alternator charges the battery and powers the car’s electrical systems. If it fails, the battery will quickly drain, leading to starting issues. Symptoms include dimming lights, a dead battery, or electrical malfunctions. Regular checks and replacements of the alternator can help maintain proper function.

Bad Spark Plugs: Worn or fouled spark plugs can fail to ignite the fuel-air mixture in the engine, leading to starting issues or rough running. Symptoms include difficulty starting, misfires, and poor fuel economy. Regular inspection and replacement of spark plugs can maintain optimal engine performance.

Clogged Air Filter: A clogged air filter can restrict air flow to the engine, causing starting issues or poor engine performance. Symptoms include difficulty starting, engine sputtering, and reduced power. Regularly replacing the air filter as part of maintenance can prevent clogging and ensure efficient air delivery.

- Faulty Camshaft or Crankshaft Sensor: A faulty camshaft or crankshaft sensor disrupts the engine’s timing and fuel injection processes, leading to starting issues, misfires, and stalling. Symptoms include the check engine light illuminating, poor acceleration, and difficulty starting. Replacing the malfunctioning sensor restores proper engine function and performance.

Security System Issues: Malfunctions in the car’s security system can prevent the engine from starting by not allowing the ignition to engage. Symptoms include the engine not cranking, the security light flashing, or the key fob not working. Resetting or repairing the security system is often required.

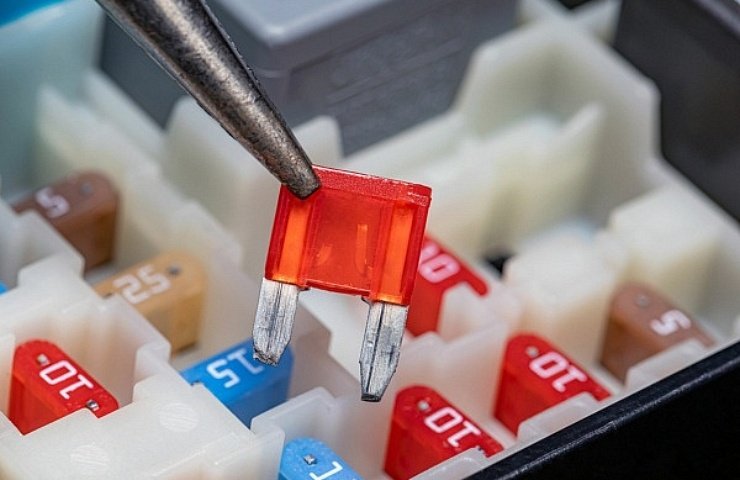

- Blown Fuse: A blown fuse interrupts the electrical circuit, causing a loss of power to the affected component. Common causes include circuit overloads, short circuits, or faulty electrical components. Symptoms include non-functioning lights, accessories, or other electrical failures. Replacing the blown fuse with one of the correct rating restores functionality.

Engine Mechanical Problems: Severe mechanical issues, such as a broken timing belt or lack of compression, can prevent the engine from starting. Symptoms include unusual noises, the engine turning over without starting, and engine misfires. Addressing these issues often requires extensive repairs and professional diagnostics.

Let’s Explore These Common Issues. Chances Are One of Them May Get You Back on The Road

Dead Battery: Causes, Symptoms, Testing, and Repair

A dead or weak battery is one of the most common reasons why a car won’t start. The battery is responsible for providing the electrical power necessary to start the engine, and when it goes bad, it can leave you stranded.

Symptoms of a Dead Battery

- No Start: When you turn the key or press the start button, nothing happens.

- Clicking Sound: A rapid clicking noise when trying to start the car is a sign of insufficient power reaching the starter motor.

- Dim Lights: Headlights and interior lights are noticeably dim or don’t turn on at all.

- Dashboard Warning: The battery warning light on the dashboard might illuminate.

Causes of a Dead Battery

- Age: Batteries typically last 3-5 years. As they age, their ability to hold a charge diminishes.

- Parasitic Drain: Leaving lights, radio, or other electrical components on when the car is off.

- Extreme Temperatures: Both hot and cold temperatures can affect battery performance.

- Faulty Alternator: If the alternator isn’t charging the battery properly, it will eventually drain.

How to Test a Battery

- Visual Inspection: Check for corrosion on the battery terminals and ensure the connections are tight.

- Multimeter: Use a multimeter to measure the battery’s voltage. A fully charged battery should read around 12.6 volts. If it’s below 12.4 volts, the battery might be weak.

- Load Test: Many auto parts stores offer free battery load testing to determine if the battery can hold a charge under load.

Repair and Replacement

If the battery is confirmed dead or weak, the solution is to replace it. Ensure you choose a battery that meets your car’s specifications. Installation is straightforward: disconnect the negative cable first, then the positive, remove the old battery, and reverse the process for the new one.

For a wide selection of quality car batteries, visit O’Reilly Auto Parts.

Regular maintenance and testing can help prevent unexpected battery failures and ensure your car starts reliably every time.

Faulty Starter Motor: Causes, Symptoms, Testing, and Repair

A faulty starter motor can prevent your car from starting, leaving you frustrated and stranded. The starter motor is crucial as it turns the engine over, allowing it to begin running. When it fails, the engine won’t start despite the battery being fully charged.

Symptoms of a Faulty Starter Motor

- Clicking Noise: When you turn the key or press the start button, you may hear a single or rapid clicking noise, indicating the starter motor is attempting to engage but failing.

- No Noise: Sometimes, there is no noise at all, signifying that the starter motor isn’t receiving power or is completely non-functional.

- Intermittent Starting: The car may start sometimes and fail at other times, pointing to a starter motor that is beginning to fail.

- Engine Doesn’t Crank: The most obvious sign is when the engine does not crank at all, despite the battery and other components being in good condition.

Causes of a Faulty Starter Motor

- Wear and Tear: Over time, the components within the starter motor, such as the brushes and armature, can wear out.

- Electrical Issues: Faulty wiring or a bad connection can prevent the starter motor from receiving adequate power.

- Solenoid Problems: The starter solenoid can fail, preventing the starter motor from engaging.

How to Test a Starter Motor

- Voltage Check:To perform a voltage check on a starter motor, use a multimeter to measure the voltage at the starter’s terminals while attempting to start the car. Connect the multimeter’s positive lead to the starter’s positive terminal and the negative lead to a ground point. The reading should be close to the battery’s voltage (around 12.6 volts). Low or no voltage indicates an issue with the power supply, wiring, or connections.

- Bench Test:

A bench test for a starter involves removing the starter motor from the vehicle and connecting it to a power source. Secure the starter in a vise, then connect the positive terminal of a battery to the starter’s positive terminal and the negative terminal to the starter’s casing. Briefly touch a wire from the battery’s positive terminal to the starter solenoid terminal. If the starter motor engages and spins, it is functioning properly.

Repair and Replacement

If the starter motor is faulty, replacement is usually the best option. Replacing a starter motor involves disconnecting the battery, removing the faulty starter, and installing a new one.

For a wide selection of quality starter motors, visit NAPA Auto Parts.

Regular checks and prompt replacement of a failing starter motor can ensure your car starts reliably and avoids unexpected breakdowns.

Ignition System Issues: Causes, Symptoms, Testing, and Repair

The ignition system is crucial for starting your car and ensuring it runs smoothly. When issues arise, you may experience starting problems, engine misfires, and reduced performance. Common symptoms include difficulty starting, rough idling, and poor fuel economy. Regular maintenance can help prevent ignition system failures and keep your vehicle operating efficiently.

Symptoms of Ignition System Issues

- Engine Misfires: Irregular combustion can cause the engine to misfire, leading to rough idling and reduced power.

- Starting Problems: Difficulty starting the car or complete failure to start, especially in cold weather, can indicate ignition issues.

- Poor Fuel Economy: Faulty ignition components can result in inefficient fuel combustion, leading to increased fuel consumption.

- Check Engine Light: The check engine light may illuminate due to sensor readings indicating ignition problems.

- Engine Stalling: Sudden engine stalls, especially when the car is idling, can be a sign of ignition system failure.

Causes of Ignition System Issues

- Worn Spark Plugs: Over time, spark plugs can wear out or become fouled, reducing their ability to ignite the fuel-air mixture.

- Faulty Ignition Coils: Ignition coils can degrade or fail, causing weak or no spark.

- Bad Ignition Wires: Damaged or deteriorated ignition wires can cause poor electrical connectivity.

- Defective Ignition Module: The ignition control module can fail, disrupting the timing of the spark.

How to Test the Ignition System

- Visual Inspection: Check spark plugs, wires, and coils for signs of wear, damage, or corrosion.

- Spark Test: Remove a spark plug, reconnect it to the ignition wire, and ground it to the engine. Crank the engine and observe the spark. A weak or absent spark indicates a problem.

- Multimeter Test: Use a multimeter to check the resistance of ignition coils and wires to ensure they are within the manufacturer’s specifications.

Repair and Replacement

Depending on the diagnosis, repairs may involve replacing spark plugs, ignition coils, wires, or the ignition control module. Regular maintenance and timely replacement of these components can prevent ignition system failures and ensure optimal engine performance.

For more detailed information on ignition systems, visit AutoZone’s Ignition Systems Guide.

Regular checks and maintenance of the ignition system can help ensure your car starts reliably and runs smoothly, preventing unexpected breakdowns and costly repairs.

What to do if your Car won’t Start from ChrisFix

Fuel System Issues: Causes, Symptoms, and Diagnosis

The fuel system in your car is crucial for delivering the right amount of fuel to the engine for combustion. When issues arise within the fuel system, it can lead to a variety of performance problems and potentially leave you stranded. Here’s a detailed look at common fuel system issues and their symptoms:

Symptoms of Fuel System Issues

Engine Cranks But Doesn’t Start:

- If the engine cranks but fails to start, this is often a sign of fuel delivery problems. Common causes include a faulty fuel pump, which can’t supply fuel to the engine, a clogged fuel filter that blocks fuel flow, electrical issue, or simply an empty fuel tank. Diagnosing this issue involves checking the fuel pump’s functionality, ensuring the fuel filter is clean, and verifying the fuel level in the tank.

Engine Stalls:

- An engine that starts but then stalls shortly after may be experiencing intermittent fuel flow. This can be caused by a failing fuel pump that provides inconsistent pressure or a clogged fuel filter restricting fuel delivery. The stalling can occur at idle or while driving, leading to a sudden loss of power. Diagnosing this involves inspecting the fuel pump’s pressure and checking the fuel filter for blockages.

Poor Acceleration:

- Poor acceleration or hesitation when trying to speed up can indicate insufficient fuel pressure or a partially blocked fuel filter. When the fuel system cannot deliver adequate fuel, the engine struggles to generate power. This issue is often felt as a lag when pressing the accelerator. Testing fuel pressure and inspecting the fuel filter can help identify and resolve this problem, ensuring the engine receives a proper fuel supply.

Rough Idling:

- Rough idling occurs when the engine runs unevenly or shakes while idling, which can be due to problems with the fuel injectors. Clogged or malfunctioning fuel injectors fail to deliver the right amount of fuel to the engine, causing an irregular idle. This issue can often be diagnosed by inspecting the fuel injectors for blockages and ensuring they are operating correctly, sometimes requiring professional cleaning or replacement.

Check Engine Light:

- The check engine light may illuminate due to various fuel system issues detected by the vehicle’s computer. Fault codes related to low fuel pressure, faulty fuel injectors, or a malfunctioning fuel pump can trigger this warning. Using an OBD-II scanner to retrieve and interpret these codes can help pinpoint the specific problem within the fuel system, allowing for targeted repairs to restore proper engine function.

Poor Fuel Economy:

- Inefficient combustion resulting from fuel system issues can lead to poor fuel economy. If the fuel system is not delivering the correct amount of fuel, the engine may burn more fuel than necessary to achieve the same power output. This results in increased fuel consumption and higher costs. Diagnosing this involves checking the fuel injectors, fuel pump, and fuel filter to ensure optimal performance and fuel delivery.

Fuel Odor:

- A strong smell of gasoline around the vehicle is a clear sign of a fuel leak, which can be both a performance issue and a safety hazard. Leaks can occur in the fuel lines, fuel tank, or around the fuel injectors. Identifying and repairing the source of the leak is crucial to prevent fuel loss, improve fuel efficiency, and reduce the risk of fire. Regular inspection of fuel system components can help detect and address leaks early.

Diagnosing Fuel System Issues

- Visual Inspection: Check for visible fuel leaks or damaged components, such as fuel lines and the fuel tank.

- Fuel Pressure Test: Use a fuel pressure gauge to test the fuel pressure at the fuel rail. Low pressure can indicate a failing fuel pump or a clogged fuel filter.

- OBD-II Scanner: Use an OBD-II scanner to check for any fault codes related to the fuel system. Codes related to fuel pressure, injector performance, and fuel delivery can help pinpoint the issue.

- Listen for the Fuel Pump: When turning the key to the “on” position (without starting the engine), listen for a humming sound from the fuel tank area. No sound may indicate a faulty fuel pump. (If fuel pump is not turning on, test to see if it is getting power.)

Fuel system issues can significantly affect your car’s performance and reliability. Regular maintenance, such as replacing the fuel filter and keeping an eye on fuel system components, can help prevent these problems. If you experience any of these symptoms, it’s important to diagnose and address the issue promptly to avoid more severe damage.

For more detailed information on diagnosing and repairing fuel system issues, visit YourMechanic’s Guide to Fuel System Issues.

Bad Alternator: Causes, Symptoms, Testing, and Repair

The alternator is a crucial component of your car’s electrical system, responsible for charging the battery and powering the electrical systems while the engine is running. When the alternator fails, it can lead to a range of problems that can affect the vehicle’s performance and reliability. Understanding the causes, symptoms, and how to test and repair a bad alternator can help you maintain your vehicle’s health.

Causes of a Bad Alternator

- Wear and Tear: Over time, the internal components of the alternator, such as the bearings, brushes, and rotor, can wear out. This is a natural process due to the continuous operation of the alternator.

- Heat Damage: Excessive heat can damage the alternator’s internal components. This can be due to poor ventilation, high engine temperatures, or electrical overload.

- Electrical Overloads: Using high-power electrical accessories can overload the alternator, causing it to fail prematurely. This includes aftermarket audio systems, lights, and other accessories.

- Faulty Voltage Regulator: The voltage regulator controls the amount of voltage the alternator sends to the battery. If it fails, it can lead to undercharging or overcharging, both of which can damage the alternator.

- Fluid Leaks: Leaks from other parts of the engine, such as oil or coolant, can contaminate the alternator and cause it to fail.

Symptoms of a Bad Alternator

- Dim or Flickering Lights: One of the first signs of a failing alternator is dim or flickering headlights and interior lights. This happens because the alternator isn’t providing enough power to the electrical system.

- Battery Warning Light: Most vehicles have a battery warning light on the dashboard that illuminates when there’s an issue with the charging system. This light might come on if the alternator is failing.

- Electrical Failures: Issues such as power windows, seats, or radio not working properly can indicate an alternator problem. The alternator is not providing sufficient power to run these systems.

- Dead Battery: A failing alternator can cause the battery to die repeatedly. If you find yourself jump-starting your car often, the alternator might be the culprit.

- Strange Noises: Hearing a growling or whining noise from the engine bay can indicate alternator problems. This is often caused by worn bearings inside the alternator.

- Engine Stalling: The engine might stall or have difficulty starting if the alternator isn’t charging the battery properly. This is because the battery isn’t getting recharged while driving.

How to Test a Bad Alternator

- Visual Inspection: Look for any signs of physical damage, such as cracks or leaks. Check the belt for wear and tension.

- Battery Voltage Test: Use a multimeter to check the battery voltage with the engine off and then with the engine running. A healthy alternator should provide a voltage between 13.8 to 14.8 volts when the engine is running.

- Load Test: Perform a load test to see if the alternator can maintain voltage under a load. This can be done at many auto parts stores or by a professional mechanic.

- Check Connections: Ensure all electrical connections to and from the alternator are clean, tight, and free of corrosion.

Repair and Replacement

If testing confirms that the alternator is faulty, replacement is often the best course of action. Here are the steps involved:

- Disconnect the Battery: Always disconnect the battery before working on the electrical system to prevent any accidents.

- Remove the Alternator: Loosen the belt tensioner to remove the drive belt, then disconnect the wiring and remove the bolts holding the alternator in place.

- Install the New Alternator: Place the new alternator in position, secure it with bolts, reconnect the wiring, and reattach the drive belt.

- Reconnect the Battery: Once everything is in place, reconnect the battery and start the engine to check the alternator’s output.

For more detailed information on alternator issues and high-quality replacement parts, visit AutoZone’s Alternator Guide.

Regular maintenance and prompt attention to the symptoms of a bad alternator can prevent unexpected breakdowns and keep your vehicle running smoothly.

Faulty Spark Plugs: Causes, Symptoms, Testing, and Repair

Spark plugs are a vital component of your car’s ignition system, responsible for igniting the air-fuel mixture in the engine’s cylinders. When spark plugs become faulty, they can cause a range of performance issues. Understanding the causes, symptoms, and how to test and repair faulty spark plugs is crucial for maintaining your vehicle’s health and efficiency.

Causes of Faulty Spark Plugs

- Wear and Tear: Over time, spark plugs naturally wear out. The electrode material can erode due to the high temperatures and pressures within the combustion chamber.

- Carbon Buildup: Incomplete combustion can lead to carbon deposits building up on the spark plug, which can interfere with the spark.

- Oil Fouling: Oil leaking into the combustion chamber, often due to worn piston rings or valve seals, can coat the spark plug and prevent proper sparking.

- Incorrect Spark Plug Type: Using spark plugs that do not meet the manufacturer’s specifications can lead to poor performance and early failure.

- Overheating: High temperatures in the engine can cause spark plug damage, leading to pre-ignition or detonation, which can further damage the plugs.

Symptoms of Faulty Spark Plugs

- Engine Misfires: A common sign of faulty spark plugs is engine misfires. The engine may run rough, and you may feel a jerking or hesitation during acceleration.

- Poor Fuel Economy: Faulty spark plugs can lead to inefficient combustion, causing the engine to use more fuel than necessary.

- Difficulty Starting: If the spark plugs are not providing a strong enough spark, the engine may struggle to start, particularly in cold weather.

- Rough Idling: The engine may idle roughly, with noticeable vibrations and uneven RPMs, due to inconsistent combustion.

- Loss of Power: You may experience a lack of acceleration and overall reduced engine performance, as faulty spark plugs can’t ignite the air-fuel mixture efficiently.

- Check Engine Light: The car’s onboard diagnostics system may detect misfires or inefficient combustion, triggering the check engine light.

How to Test Spark Plugs

- Visual Inspection: Remove the spark plugs and inspect them for signs of wear, carbon buildup, oil fouling, or physical damage. A healthy spark plug should have a light tan or grayish color.

- Spark Test: Use a spark plug tester to check if the spark plug is generating a strong spark. Attach the tester to the spark plug and ground it to the engine, then crank the engine and observe the spark.

- Multimeter Test: Measure the resistance of the spark plug using a multimeter. High resistance can indicate a worn or damaged spark plug.

Repair and Replacement

If spark plugs are found to be faulty, replacement is necessary. Here’s how to replace spark plugs:

- Gather Tools and Parts: You’ll need a spark plug socket, ratchet, extension bar, and a torque wrench. Ensure you have the correct replacement spark plugs as specified by your vehicle’s manufacturer.

- Disconnect the Battery: For safety, disconnect the battery before starting the replacement process.

- Remove Old Spark Plugs: Remove the ignition coil or spark plug wire to access the spark plugs. Use the spark plug socket and ratchet to unscrew and remove the old spark plugs.

- Inspect and Gap New Spark Plugs: Check the gap on the new spark plugs using a gap gauge and adjust if necessary to meet the manufacturer’s specifications.

- Install New Spark Plugs: Carefully screw in the new spark plugs by hand to avoid cross-threading. Then, use the torque wrench to tighten them to the specified torque.

- Reconnect Components: Reattach the ignition coils or spark plug wires, ensuring they are properly seated.

- Reconnect the Battery: Reconnect the battery and start the engine to ensure everything is functioning correctly.

Faulty spark plugs can significantly impact your vehicle’s performance, fuel economy, and reliability. Regular inspection and timely replacement of spark plugs are essential for maintaining optimal engine performance. For more detailed information on spark plugs and high-quality replacement parts, visit NGK Spark Plugs.

By staying proactive with your spark plug maintenance, you can ensure smooth engine operation, improved fuel efficiency, and reduced emissions.

Clogged Air Filter: Causes, Symptoms, Testing, and Repair

The air filter in your car plays a crucial role in keeping the engine running smoothly by filtering out dust, dirt, and other contaminants from the air before it enters the engine. A clogged air filter can lead to a range of performance issues, affecting fuel efficiency, engine power, and overall drivability. Understanding the causes, symptoms, and how to test and replace a clogged air filter is essential for maintaining your vehicle’s health.

Causes of a Clogged Air Filter

- Environmental Factors: Driving in dusty or sandy environments can cause the air filter to clog more quickly. Construction zones, dirt roads, and areas with high pollution levels contribute to faster air filter degradation.

- Lack of Maintenance: Neglecting regular maintenance and not replacing the air filter according to the manufacturer’s recommended schedule can lead to clogging.

- Driving Conditions: Frequent short trips and city driving with lots of stop-and-go traffic can cause the air filter to become dirty faster compared to highway driving.

Symptoms of a Clogged Air Filter

- Reduced Engine Performance: A clogged air filter restricts airflow to the engine, leading to a noticeable reduction in engine power and acceleration.

- Poor Fuel Economy: When the engine doesn’t get enough air, it compensates by using more fuel, resulting in decreased fuel efficiency.

- Black Smoke from Exhaust: Insufficient air supply can cause incomplete combustion, leading to black smoke coming from the exhaust pipe.

- Engine Misfires: Restricted airflow can cause the air-fuel mixture to become too rich, resulting in engine misfires, rough idling, and hesitation during acceleration.

- Check Engine Light: A clogged air filter can trigger the check engine light due to sensors detecting abnormal air intake or combustion issues.

- Unusual Engine Sounds: Whistling or hissing noises from the engine compartment can indicate restricted airflow due to a clogged air filter.

How to Test an Air Filter

- Visual Inspection: Remove the air filter from its housing and hold it up to the light. If you cannot see light passing through most of the filter, it’s likely clogged and needs replacement.

- Tap Test: Gently tap the air filter on a hard surface to dislodge loose dirt and debris. If a significant amount of dirt falls out, it indicates the filter is clogged and should be replaced.

- Mileage Check: If you’ve driven more than the recommended mileage (usually 12,000 to 15,000 miles) since the last air filter change, it’s a good idea to replace it, even if it looks clean.

Repair and Replacement

Replacing a clogged air filter is a straightforward process that can be done with minimal tools and time. Here’s how to replace your car’s air filter:

- Gather Tools and Parts: You’ll need a new air filter and, in some cases, a screwdriver to open the air filter housing.

- Locate the Air Filter Housing: The air filter housing is usually a black plastic box near the engine. Consult your owner’s manual if you’re unsure.

- Open the Housing: Release the clips or remove the screws holding the air filter housing cover in place.

- Remove the Old Air Filter: Take out the old air filter and dispose of it properly.

- Clean the Housing: Wipe out any dirt or debris from the air filter housing with a clean cloth.

- Install the New Air Filter: Place the new air filter into the housing, ensuring it fits snugly and correctly.

- Close the Housing: Secure the air filter housing cover back in place with the clips or screws.

- Check the Installation: Ensure everything is properly secured and there are no gaps or loose connections.

A clogged air filter can significantly impact your vehicle’s performance and fuel efficiency. Regular inspection and timely replacement of the air filter are crucial for maintaining optimal engine performance and longevity. For more detailed information on air filters and high-quality replacement parts, visit K&N Filters.

By staying proactive with air filter maintenance, you can ensure your engine receives the clean air it needs to run efficiently, improving fuel economy, reducing emissions, and extending the life of your vehicle.

Faulty Camshaft or Crankshaft Sensor: Causes, Symptoms, Testing, and Repair

Camshaft and crankshaft sensors are essential components of your car’s engine management system. These sensors monitor the position and speed of the camshaft and crankshaft, providing critical data to the engine control unit (ECU) for precise fuel injection and ignition timing. When either sensor fails, it can lead to a range of performance issues and driveability problems. Understanding the causes, symptoms, and how to test and repair these sensors is crucial for maintaining your vehicle’s health.

Causes of Faulty Camshaft or Crankshaft Sensors

- Wear and Tear: Over time, these sensors can wear out due to continuous exposure to high temperatures and vibrations from the engine.

- Electrical Issues: Problems such as short circuits, corrosion, or damaged wiring can cause sensor failure. Electrical interference from other engine components can also affect sensor performance.

- Contamination: Oil, dirt, and debris can contaminate the sensors, affecting their ability to accurately read and transmit data to the ECU.

- Physical Damage: Impact from debris or incorrect installation can physically damage the sensors, leading to failure.

- Heat Damage: Prolonged exposure to extreme engine heat can cause the sensors to malfunction or fail.

Symptoms of Faulty Camshaft or Crankshaft Sensors

- Check Engine Light: One of the most common symptoms is the illumination of the check engine light on the dashboard. The ECU will detect irregular signals from the sensors and store diagnostic trouble codes (DTCs).

- Engine Misfires: Faulty sensors can cause incorrect timing of the fuel injection and ignition, leading to engine misfires, rough idling, and hesitation during acceleration.

- Starting Issues: Difficulty starting the engine or extended cranking time can indicate a problem with the crankshaft sensor, as it’s crucial for determining the engine’s position during startup.

- Stalling: Intermittent stalling or the engine shutting off unexpectedly while driving can be a sign of a failing camshaft or crankshaft sensor.

- Poor Acceleration: A decrease in acceleration performance or a lack of power, especially during sudden acceleration, can indicate sensor issues affecting the engine’s timing.

- Erratic Speedometer Readings: In some cases, faulty sensors can cause erratic or incorrect speedometer readings, as the ECU may receive inaccurate data about the engine’s speed.

How to Test Camshaft and Crankshaft Sensors

- Visual Inspection: Inspect the sensors and their wiring for any visible signs of damage, corrosion, or contamination.

- OBD-II Scanner: Use an OBD-II scanner to check for any stored diagnostic trouble codes (DTCs) related to the sensors. Common codes include P0340 (Camshaft Position Sensor Circuit) and P0335 (Crankshaft Position Sensor Circuit).

- Multimeter Test: Test the sensors’ electrical resistance and voltage output using a multimeter. Compare the readings with the manufacturer’s specifications to determine if the sensors are functioning correctly.

- Oscilloscope Test: For a more detailed analysis, an oscilloscope can be used to view the sensor’s signal pattern. This helps identify any irregularities or inconsistencies in the signal.

Repair and Replacement

If testing confirms that the camshaft or crankshaft sensors are faulty, replacement is usually the best option. Here’s how to replace these sensors:

- Gather Tools and Parts: You’ll need the correct replacement sensor(s), a ratchet, sockets, and possibly a screwdriver.

- Disconnect the Battery: For safety, disconnect the battery before starting the replacement process.

- Locate the Sensor: Refer to your vehicle’s service manual to locate the camshaft or crankshaft sensor. The camshaft sensor is usually located near the top of the engine, while the crankshaft sensor is typically located near the bottom.

- Remove the Old Sensor: Disconnect the electrical connector, remove any mounting bolts or screws, and carefully remove the old sensor.

- Install the New Sensor: Position the new sensor, secure it with bolts or screws, and reconnect the electrical connector.

- Reconnect the Battery: Once the new sensor is installed, reconnect the battery and start the engine to ensure proper operation.

- Clear DTCs: Use an OBD-II scanner to clear any stored diagnostic trouble codes and reset the check engine light.

Faulty camshaft or crankshaft sensors can significantly impact your vehicle’s performance and reliability. Regular inspection and timely replacement of these sensors are essential for maintaining optimal engine performance. For more detailed information on camshaft and crankshaft sensors and high-quality replacement parts, visit AutoZone’s Sensor Guide.

By staying proactive with sensor maintenance, you can ensure accurate engine timing, improved fuel efficiency, and a smooth-running vehicle, preventing unexpected breakdowns and costly repairs.

Faulty Security System: Causes, Symptoms, Testing, and Repair

Modern vehicles come equipped with sophisticated security systems designed to prevent theft and unauthorized access. These systems typically include alarms, immobilizers, and keyless entry mechanisms. While these features enhance vehicle security, a malfunctioning security system can lead to various issues, including the inability to start the car. Understanding the causes, symptoms, and how to diagnose and repair a faulty security system is crucial for maintaining your vehicle’s functionality and security.

Causes of a Faulty Security System

- Key Fob Issues: Dead or weak batteries in the key fob can prevent it from communicating with the vehicle’s security system.

- Worn Key: Over time, physical keys can wear out, making it difficult for the system to recognize them.

- Faulty Immobilizer: The immobilizer, which prevents the engine from starting without the correct key, can fail due to electronic malfunctions.

- Wiring Problems: Damaged or corroded wiring can disrupt the communication between the key fob, immobilizer, and the car’s ECU.

- Malfunctioning Alarm System: A faulty alarm system can cause false alarms, prevent the car from starting, or fail to arm/disarm correctly.

- Software Glitches: Software issues within the car’s ECU can lead to security system malfunctions.

Symptoms of a Faulty Security System

- Car Won’t Start: One of the most common symptoms is the car not starting, even though the battery and starter are functioning properly. The immobilizer may not recognize the key.

- Alarm Issues: The alarm might go off randomly or fail to activate, indicating a problem with the alarm system.

- Key Fob Problems: Difficulty locking or unlocking the doors with the key fob can indicate a security system issue.

- Security Light: The security or anti-theft light on the dashboard may stay on or flash, indicating a problem with the system.

- Intermittent Starting Problems: The car may start intermittently, making it unreliable.

How to Test a Faulty Security System

- Check Key Fob Battery: Replace the key fob battery and see if it resolves the issue. A weak or dead battery is a common cause of key fob problems.

- Inspect the Key: Examine the physical key for signs of wear. If it’s a transponder key, make sure the chip inside is intact.

- Security Light Diagnosis: Observe the security light on the dashboard. Refer to the vehicle’s manual to understand the different blinking patterns, which can indicate specific issues.

- OBD-II Scanner: Use an OBD-II scanner to check for any security system-related error codes stored in the vehicle’s ECU.

- Wiring Inspection: Visually inspect the wiring related to the security system for signs of damage, corrosion, or loose connections.

Repair and Replacement

If testing confirms that there is an issue with the security system, the following steps can be taken to resolve it:

- Replace Key Fob Battery: If the key fob battery is dead or weak, replace it with a new one and test the system.

- Reprogram Key Fob: If the key fob is not communicating with the car, reprogram it according to the vehicle’s manual or have a professional do it.

- Repair or Replace Immobilizer: If the immobilizer is faulty, it may need to be reset, repaired, or replaced by a professional mechanic.

- Fix Wiring Issues: Repair any damaged or corroded wiring to ensure proper communication between the key fob, immobilizer, and ECU.

- Software Update: Update the vehicle’s ECU software if there are known issues that can be resolved through a firmware update.

- Alarm System Maintenance: Ensure the alarm system is functioning correctly by inspecting and, if necessary, replacing faulty components.

A faulty security system can cause significant inconvenience and potentially leave your vehicle vulnerable. Regular maintenance and timely repairs are essential for ensuring the security system functions correctly. For more detailed information on diagnosing and repairing security system issues, visit YourMechanic’s Guide to Car Security Systems.

By staying proactive with security system maintenance, you can ensure reliable vehicle access, prevent unexpected starting issues, and maintain your vehicle’s overall security.

Blown Fuse: Causes, Symptoms, Testing, and Repair

A blown fuse can cause various electrical issues in your vehicle, from malfunctioning lights to non-working accessories. Fuses are designed to protect your car’s electrical circuits by breaking the connection when excessive current flows through the circuit. Understanding the causes, symptoms, and how to test and replace a blown fuse is essential for maintaining your vehicle’s electrical system.

Causes of a Blown Fuse

- Overloaded Circuit: When too many electrical devices are connected to a single circuit, the current can exceed the fuse’s rating, causing it to blow.

- Short Circuit: A short circuit occurs when a hot wire (positive) touches a ground wire (negative), creating a surge of electricity that the fuse can’t handle.

- Faulty Electrical Component: Malfunctioning components such as a motor, relay, or sensor can draw too much current, blowing the fuse.

- Corrosion or Moisture: Corrosion or moisture in the fuse box or connections can create resistance and increase current flow, leading to a blown fuse.

- Wiring Problems: Damaged or frayed wires can cause short circuits or increased resistance, resulting in blown fuses.

Symptoms of a Blown Fuse

- Electrical Component Failure: The most obvious symptom is the failure of an electrical component, such as headlights, interior lights, radio, or power windows.

- Multiple Malfunctions: If several electrical components fail simultaneously, it could indicate a blown fuse that controls a shared circuit.

- No Power to Circuit: A complete lack of power to a specific circuit or component often points to a blown fuse.

- Burnt Smell: A burnt smell around the fuse box can indicate a blown fuse or electrical issue.

- Fuse Box Inspection: Upon inspection, a blown fuse will appear visibly damaged, with a broken filament or discolored glass.

How to Test a Blown Fuse

- Visual Inspection: Remove the fuse from the fuse box and hold it up to the light. A blown fuse will have a broken filament or appear blackened.

- Multimeter Test: Set a multimeter to the continuity setting and place the probes on the fuse terminals. A continuous beep or reading indicates a good fuse, while no sound or reading indicates a blown fuse.

- Test Light: Using a test light, touch one end to the fuse terminal and the other to a ground. If the test light does not illuminate, the fuse is blown.

Repair and Replacement

Replacing a blown fuse is a straightforward process that can be done with minimal tools:

- Identify the Blown Fuse: Consult your vehicle’s manual to locate the fuse box and identify the fuse corresponding to the malfunctioning component.

- Turn Off the Ignition: Ensure the vehicle’s ignition is off to prevent electrical shock or further damage.

- Remove the Blown Fuse: Use a fuse puller or a pair of needle-nose pliers to carefully remove the blown fuse from its socket.

- Inspect and Replace: Check the fuse for visible damage and replace it with a new fuse of the same amperage rating. Using a fuse with a higher rating can cause further damage to the electrical system.

- Test the Component: Turn on the ignition and test the previously malfunctioning component to ensure the new fuse has resolved the issue.

Preventive Measures

- Regular Inspection: Periodically inspect the fuses and fuse box for signs of corrosion or damage.

- Avoid Overloading Circuits: Do not connect too many devices to a single circuit, especially high-power accessories.

- Maintain Electrical Components: Regularly check and maintain all electrical components to ensure they are not drawing excessive current.

- Keep Fuse Box Dry: Ensure the fuse box is sealed and dry to prevent moisture-related issues.

A blown fuse can cause various electrical problems in your vehicle, but it is a relatively simple issue to diagnose and fix. Regular inspection and maintenance of the electrical system can help prevent blown fuses and ensure all components function correctly. For more detailed information on diagnosing and repairing fuse-related issues, visit AutoZone’s Guide to Fuses.

By understanding the causes, symptoms, and proper procedures for handling blown fuses, you can maintain your vehicle’s electrical health and avoid unexpected failures.

Engine Mechanical Problems: Causes, Symptoms, and Solutions

Severe mechanical issues, such as a broken timing belt or lack of compression, can prevent the engine from starting. Symptoms include unusual noises, the engine turning over without starting, and engine misfires. Addressing these issues often requires extensive repairs and professional diagnostics.

Causes of Engine Mechanical Problems

- Lack of Maintenance: Regular maintenance is crucial for engine health. Skipping oil changes, ignoring filter replacements, and neglecting other routine services can lead to severe engine wear and tear.

- Overheating: Engine overheating can cause significant damage, including warped cylinders, blown head gaskets, and cracked engine blocks. Overheating can result from coolant leaks, a malfunctioning thermostat, or a failing water pump.

- Wear and Tear: Over time, components like the timing belt, pistons, and valves naturally wear out. High mileage and harsh driving conditions can accelerate this wear.

- Contamination: Dirt, debris, and sludge can accumulate in the engine, leading to blocked oil passages and increased friction. Contaminants can enter through a faulty air filter or from using poor-quality oil.

- Misfiring: Repeated misfires due to issues in the ignition or fuel system can cause damage to engine components over time, leading to more significant mechanical failures.

Symptoms of Engine Mechanical Problems

- Unusual Noises: Knocking, tapping, or grinding noises from the engine often indicate serious internal issues like worn bearings, a failing timing chain, or piston problems.

- Check Engine Light: This warning light can signal numerous problems, including mechanical issues. Diagnostic trouble codes (DTCs) can help pinpoint the exact issue.

- Poor Performance: Loss of power, sluggish acceleration, and decreased fuel efficiency are common signs of mechanical problems. These symptoms suggest that the engine isn’t operating efficiently.

- Excessive Smoke: Blue smoke indicates burning oil, white smoke suggests coolant leaks (often from a blown head gasket), and black smoke indicates excessive fuel burning.

- Vibrations: Unusual vibrations, especially at idle or during acceleration, can indicate engine imbalance or failing components such as motor mounts or pistons.

- Oil Consumption: Frequent need to add oil can indicate internal leaks, worn piston rings, or other serious issues. This can lead to reduced lubrication and increased friction within the engine.

Solutions to Engine Mechanical Problems

- Regular Maintenance: Adhering to the manufacturer’s maintenance schedule is crucial. Regular oil changes, filter replacements, and timely inspections can prevent many mechanical issues.

- Address Overheating: Regularly check the coolant levels and inspect the cooling system for leaks or malfunctions. Replace the thermostat, water pump, or radiator as needed to maintain proper engine temperature.

- Replace Worn Components: Timing belts, spark plugs, and other critical components should be replaced according to the manufacturer’s recommendations. Preventive replacement can avoid catastrophic failures.

- Use Quality Parts and Fluids: Always use high-quality oil, filters, and replacement parts. Quality fluids reduce the risk of contamination and wear.

- Prompt Repairs: Addressing minor issues like misfires, oil leaks, or overheating promptly can prevent more severe damage. If the check engine light comes on, use an OBD-II scanner to identify the problem and take corrective action.

- Professional Diagnosis: For persistent or severe issues, seek professional diagnostics and repair. Mechanics can use advanced tools and techniques to accurately diagnose and fix complex mechanical problems.

Engine mechanical problems can significantly impact your vehicle’s performance and longevity. Understanding the causes and symptoms allows for timely intervention, potentially saving you from expensive repairs. Regular maintenance, quality parts, and prompt attention to minor issues can keep your engine running smoothly and efficiently. For severe or persistent problems, professional help is essential to ensure accurate diagnosis and effective repairs. Maintaining your engine’s health is critical for the overall reliability and performance of your vehicle.

Conclusion

A car that won’t start can stem from various issues ranging from a dead battery and faulty starter motor to ignition system problems, fuel system issues, or even a blown fuse. Understanding the symptoms and causes of these problems can help you diagnose and address them effectively. Regular maintenance and timely repairs are crucial for preventing these issues and ensuring your vehicle remains reliable. By being proactive and attentive to your car’s needs, you can avoid unexpected breakdowns and enjoy a smooth, trouble-free driving experience. For persistent or complex problems, seeking professional assistance is always a wise decision to ensure accurate diagnosis and effective solutions. Thank you for reading and never stop revving up your knowledge.

KC Car Products earns a commission from our sponsored links.

Contact Us At kccarproducts@gmail.com