7 Things To Consider Before Becoming a Mechanic In 2024

Explore the comprehensive guide ‘7 Things To Consider Before Becoming a Mechanic In 2024,’ covering crucial topics from tool investments and physical demands to compensation models and self-employment challenges. Learn about the potential earnings and liabilities in the mechanic industry, enriched with expert advice and key strategies for a successful career.

If you’re considering a career as a mechanic or automotive technician, or if you’re a seasoned mechanic thinking about your next steps in the auto industry, this is a pivotal time. The field is evolving rapidly with new technologies and opportunities, offering both fresh entrants and experienced professionals a chance to grow and redefine their skills in dynamic ways.

KC Car Products earns a commission from our sponsored links.

1. Buying Tools vs. Shop-Supplied Tools

Mechanics often face the decision of buying their tools or using those provided by their employers. Buying your tools can be a significant investment but offers personal choice and potentially better quality. Shop-supplied tools, however, reduce personal expenses and are maintained by the employer. The choice largely depends on the mechanic’s financial situation and long-term career plans.

Navigating Tool Choices for Aspiring and Seasoned Mechanics

Entering the world of automotive repair requires making several crucial decisions, one of which is the selection and acquisition of tools. Whether you are just starting your career as a mechanic or you are a seasoned professional considering an upgrade to your toolkit, understanding the nuances of tool ownership can significantly impact your work quality and job satisfaction.

Starting Out: Acquiring Your First Tools

For those new to the automotive field, the initial choice between opening a tool truck account, shopping online, or picking up tools at budget-friendly stores like Harbor Freight can be daunting. Each option comes with its own set of advantages and disadvantages:

Tool Truck Accounts: Purchasing tools from a tool truck offers convenience and access to high-quality, professional-grade tools. The main advantage is the ability to get tools on credit and pay over time. However, these tools can be expensive, and the debt incurred can be a burden for new technicians.

Online Shopping: Buying tools online can be less expensive and provides access to a wide range of products and reviews. It’s a great way to compare prices and find deals. The downside is that you can’t handle the tools before buying, which can lead to uncertainty about quality.

Budget Stores: Stores like Harbor Freight are popular for their affordable prices. They are suitable for those who need to acquire a basic set of tools without a significant initial investment. The quality may not match that of higher-end brands, but they often provide good enough performance for beginners.

Owning vs. Employer-Provided Tools

As you delve deeper into your career, you’ll need to decide whether to invest in owning your tools or rely on those provided by your employer.

Pros of Owning Your Tools:

- Quality and Reliability: Owning your tools allows you to invest in higher-quality items that can handle the rigors of daily use and are less likely to fail during critical tasks.

- Familiarity and Efficiency: Using your own tools can improve your efficiency, as you are familiar with the feel and performance of each item.

- Long-term Investment: Quality tools can last a lifetime. Owning your tools is a long-term investment in your career.

- Choice of Freedom: Not having to rely on your employer for tools gives you the freedom and choice to work for other shops that may potentially offer better pay. It also gives you the potential to work for yourself.

Cons of Owning Your Tools:

- Initial Cost: The upfront cost of purchasing high-quality tools can be significant, especially for those just starting out.

- Maintenance and Replacement: You are responsible for maintaining and replacing your tools, which can add to the overall cost.

Pros of Employer-Provided Tools:

- Cost-Efficiency: You can save a substantial amount of money on initial costs, maintenance, and replacements.

- Convenience: There’s no need to transport your tools to and from work, which adds an element of convenience.

Cons of Employer-Provided Tools:

- Quality and Availability: You might find yourself working with tools of lower quality or that are not ideally suited to specific tasks. Additionally, sharing tools can mean they’re not always available when you need them.

- If You Lose Your Job: If you get terminated from your shop, it will much more difficult to find employment if you do not own your own tools.

- Less Pay: More than likely, you will be started out at a lower pay rate than somebody who has their own tools.

The Benefits of Investing in High-Quality Tools

Investing in high-quality tools can transform the way you work. Good tools reduce the effort required for each job and decrease the likelihood of causing damage to parts or the vehicle. They are generally more ergonomic, which can reduce the physical strain and risk of injury over time. Moreover, high-quality tools often come with better warranties and support from manufacturers, providing peace of mind and reliability.

In conclusion, the decisions about tool acquisition are not just financial but also impact the quality of your work and professional growth. For aspiring mechanics, starting with more accessible options and gradually upgrading is a sensible path. For the seasoned mechanic, continually assessing tool needs and investing in quality upgrades is essential for maintaining efficiency and effectiveness in the workshop.

WORKPRO 408-Piece Mechanics Tool Set

Check out this perfect mechanic starter set for the person just starting out.

2. Wear on Your Body Over Time

The physical demands of being a mechanic can lead to wear and tear on the body over time. Common issues include joint pain, back problems, and hand injuries. Ergonomic practices and proper safety equipment are essential to mitigate these risks. Regular exercise and possibly consulting healthcare professionals can help manage these physical challenges.

The Risks and Safety Measures for Auto Mechanics

Auto mechanics face various occupational hazards that can impact their long-term health and well-being. Understanding these risks and implementing preventive strategies is crucial for maintaining a safe and productive work environment.

Understanding the Risks

Mechanical work is physically demanding and involves exposure to numerous risks including musculoskeletal injuries from repetitive movements, heavy lifting, and working in awkward positions. Mechanics are also exposed to hazardous chemicals, which can lead to dermatological issues and respiratory problems.

-

Musculoskeletal Disorders: These are common in the profession due to the physical nature of the work, which often requires mechanics to engage in tasks that strain the body, like lifting heavy parts or working in constrained positions. Conditions such as back injuries, carpal tunnel syndrome, and other cumulative trauma disorders are prevalent (Hoffmann Law Office) (CDC).

-

Chemical Exposure: Regular contact with solvents, fuels, and other chemicals can lead to various health issues, including skin disorders like dermatitis and respiratory problems. In extreme cases, exposure to substances like asbestos in older vehicle parts can increase the risk of serious diseases such as lung cancer (Tool Tally) (DermNet NZ).

Preventive Measures

To mitigate these risks, mechanics can adopt several safety practices and use protective gear.

Ergonomic Practices: Implementing ergonomic solutions can significantly reduce the risk of musculoskeletal disorders. This includes using lifts to handle heavy parts, adjusting workspaces to reduce the need to work in awkward positions, and ensuring tools are well-maintained and suitable for the tasks at hand (School of Public Health).

Protective Equipment: Personal Protective Equipment (PPE) is essential for minimizing exposure to harmful chemicals and reducing the risk of injuries. Gloves, goggles, and respiratory protection should be used as necessary, especially when handling chemicals or working in environments with particulate matter (Prudential Uniforms) (Canadian Profession Path).

Proper Training and Awareness: Mechanics should receive regular training on the risks associated with their work and the use of ergonomic techniques and protective equipment. Awareness of how to handle hazardous materials safely and how to operate in a mechanically demanding environment is crucial (Canadian Profession Path).

Factual Examples of Long-Term Impact

Long-Term Back Pain: Continuous heavy lifting and working in uncomfortable positions can lead to chronic back pain, which might necessitate medical intervention or even lead to disability in severe cases (Hoffmann Law Office).

Respiratory Issues from Asbestos: Historically, mechanics have faced risks from asbestos exposure, primarily through brake and clutch systems, leading to severe respiratory issues and an increased risk of lung cancer over time (Tool Tally).

By understanding these risks and adopting comprehensive safety measures, mechanics can protect themselves from immediate injuries and long-term health issues, ensuring a healthier, longer career in the automotive industry.

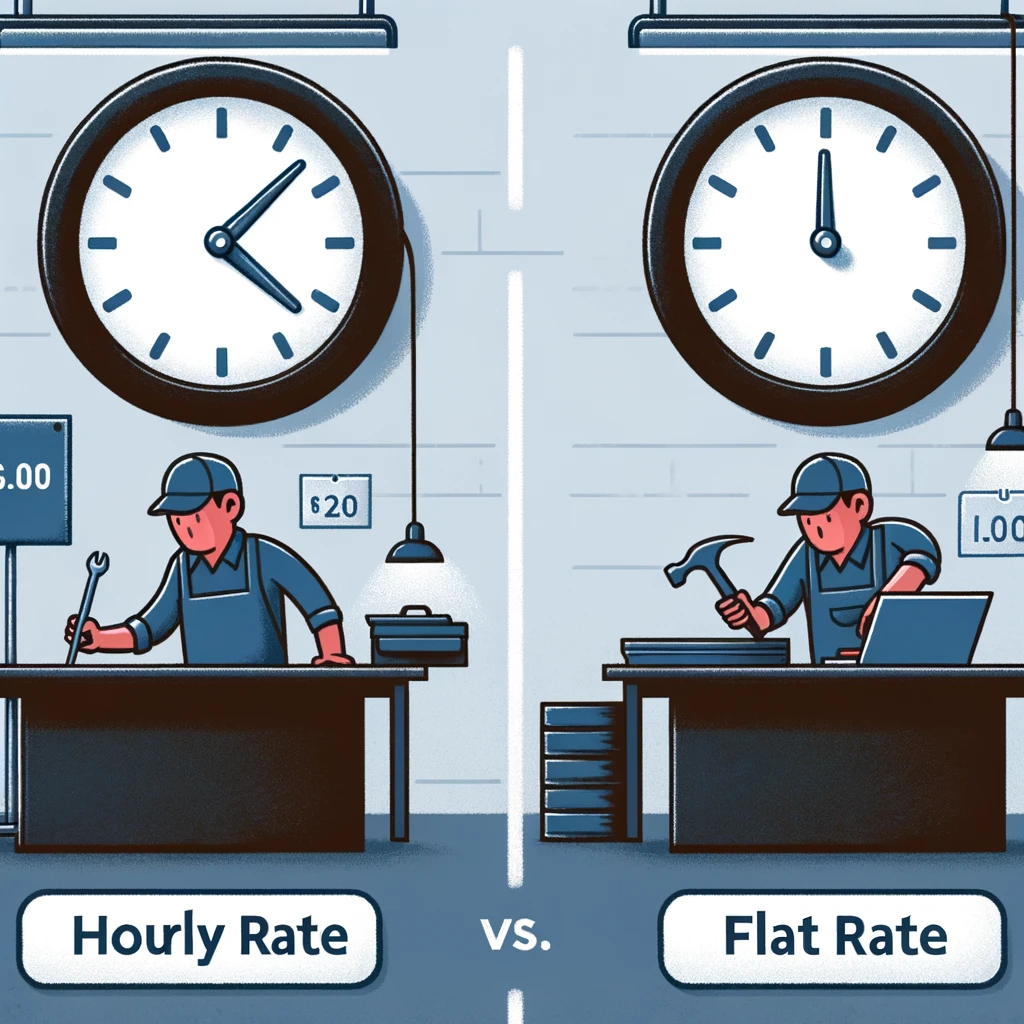

3. Flat Rate vs. Hourly Rate: Pros and Cons

Compensation for mechanics can vary significantly between flat rate and hourly rate pay systems. Flat rate pays mechanics for the jobs completed, which can incentivize fast work but may lead to inconsistent paychecks depending on workflow. Hourly rate offers consistent pay but may not incentivize efficiency as strongly as flat rate systems.

Exploring Compensation

Navigating the decision between flat rate and hourly pay systems is crucial for automotive technicians and the garages that employ them. Each system has its unique advantages and challenges, and understanding these can help individuals and businesses make informed decisions that align with their operational goals and personal career trajectories.

Flat Rate Pay System

Pros:

- Earning Potential: Technicians can potentially earn more through flat rate pay systems by completing jobs more efficiently than the allotted time. This can significantly increase earnings without extending work hours (Chris Collins).

- Productivity Incentives: The flat rate system encourages high productivity, as technicians are motivated to complete tasks faster and take on more work, potentially leading to higher overall shop throughput.

Cons:

- Income Variability: One of the major drawbacks of the flat rate system is its unpredictability. Technicians may face periods with little to no work, particularly when waiting on parts, leading to inconsistent earnings (UTI).

- Quality of Work: There is a risk of compromised work quality as technicians might rush jobs to increase their earnings. This can lead to increased comebacks (repeat repairs) and decreased customer satisfaction (Automotive CSI Training).

Hourly Pay System

Pros:

- Stability: Hourly pay provides a consistent income, as technicians are paid for every hour worked, regardless of the job or its complexity. This stability can be particularly beneficial during slow periods or when unexpected delays occur (Chris Collins).

- Quality Focus: With no pressure to beat the clock, technicians might spend more time on each task, potentially leading to higher quality repairs and greater customer satisfaction.

Cons:

- Lack of Incentives: A potential downside to hourly pay is the lack of incentives for speed or efficiency. Technicians are guaranteed the same pay irrespective of how quickly they complete their tasks, which may lead to lower overall productivity.

- Complacency Risk: There is a risk that technicians may not feel compelled to work as efficiently or to engage in upselling additional services, potentially affecting shop profitability.

Choosing the Right Pay System

The choice between flat rate and hourly pay depends on several factors including the business model, the volume and type of work, the skill level of the technicians, and the desired business outcomes. Shops might choose a flat rate to maximize productivity and profit from high-performing technicians, while others might prefer the consistency and quality assurance provided by hourly wages.

In conclusion, both systems have their merits and can be effective depending on the specific circumstances of a workshop and its staff. It is crucial for both employers and employees to clearly understand the implications of each system to foster a productive and mutually beneficial work environment.

4. Dealing with Customers Seeking Discounts

Mechanics often encounter customers seeking discounts, which can affect profitability. Establishing clear pricing policies and excellent communication skills can help manage customer expectations and maintain a fair pricing structure. Loyalty programs or occasional promotions might be strategies to satisfy both parties.

Navigating the Challenges of the Auto Mechanic Trade

Auto mechanics often face unique challenges in the trades industry. From handling side jobs for friends and family to managing customer expectations in a professional setting, mechanics must navigate a complex landscape of interpersonal and business dynamics. This article explores why mechanics are often taken advantage of, the skills needed to establish firm professional boundaries, and strategies for quoting and pricing services confidently.

Vulnerability in the Mechanic Trade

Mechanics are uniquely positioned in the trades for a few reasons that can lead to being taken advantage of more frequently than other professionals. First, the technical complexity of automotive repair means that most customers lack the knowledge to evaluate the work needed or the quality of the work done. This asymmetry of information can lead to unrealistic expectations or disputes over service charges, where customers may feel overcharged for services they don’t fully understand.

Furthermore, mechanics working in local shops or independently often deal with friends, family, or acquaintances looking for a deal. The personal connection can lead to expectations of discounts or free work, putting the mechanic in a tough position between professional standards and personal relationships. These dynamics can strain both business profitability and personal ties if not managed carefully.

Essential Skills for Establishing Boundaries and Firm Pricing

To navigate these challenges effectively, mechanics need a robust set of skills beyond their technical expertise:

Communication Skills: Clear, honest communication about what a repair will entail, the costs involved, and the expected time frame is essential. This includes providing detailed, written estimates that outline the scope of work and costs, which helps prevent disputes over what was agreed upon.

Customer Service Skills: Good customer service involves managing expectations and responding to customer concerns without compromising the quality of service or the business’s profitability.

Negotiation Skills: Mechanics often need to negotiate prices and services with customers. Establishing clear policies on pricing and discounts can help streamline these discussions and protect the business’s interests.

Legal Knowledge: Understanding the legal rights and responsibilities, including those related to mechanic’s liens and consumer protection laws, is crucial. This knowledge ensures mechanics can operate within the law and protect their business from potential legal challenges.

By mastering these skills, mechanics can safeguard their work, ensure fair compensation, and maintain good customer relationships, all while minimizing the risk of legal disputes and the stress of financial unpredictability.

5. Potential Income from Experience and Knowledge

Experienced and knowledgeable mechanics have the potential to earn significantly more than entry-level workers. Specializations in high-demand areas like electric vehicles or specific high-end brands can further increase earning potential. Continuous education and certifications, such as ASE Certification, are crucial. operating your vehicle in the most efficient way.

Navigating the Auto Mechanic Career: Education, Experience, and Earnings

Auto mechanics enter the field through different paths, each with unique benefits and challenges. Whether you’re just starting out or considering further education, understanding the landscape can help you make informed decisions.

Starting Wages: Entry-Level vs. Degree Holders

The average hourly pay for an entry-level automobile mechanic in 2024 is approximately $19.51. This rate reflects a typical starting wage for mechanics entering the field directly off the street without formal post-secondary education (PayScale).

In contrast, mechanics who begin their careers after earning a degree often have higher starting salaries. For example, an Automotive Mechanic I, typically an entry-level position for those with formal education, has an average salary of $49,811 annually (Salary.com). This suggests that formal education can potentially lead to higher initial earnings compared to entering the field without a degree.

Real-Life Experience vs. School Experience

Advantages of Real-Life Experience:

- Immediate Income: Starting work right away allows mechanics to earn and learn simultaneously, avoiding the debt often associated with education.

- Hands-On Skills: On-the-job training provides real-world experience that can be more directly applicable to everyday work in a garage or repair shop.

Disadvantages of Real-Life Experience:

- Limited Advancement: Mechanics without formal credentials may face ceilings in advancement opportunities and wage increases.

- Lack of Theoretical Knowledge: On-the-job training might not cover the broader scope of knowledge that formal education offers, potentially limiting the ability to work on more complex systems or the latest technologies.

Advantages of School Experience:

- Broad Knowledge Base: Formal education often provides a more comprehensive understanding of automotive systems, diagnostics, and repair technologies.

- Certifications and Specializations: Degree programs typically prepare and qualify students for certification exams, which are highly regarded in the industry.

Disadvantages of School Experience:

- Cost: The expense of education can be significant, leading to student debt.

- Time: Spending time in school delays entry into the workforce and the earning potential that comes with it.

Auto Repair for Beginners: A Complete DIY Guide with Step-by-Step Instructions on How to Fix All of Your Car’s Most Common Problems for Free at Home

Check out this book and broaden your knowledge about the workings of automobiles.

Understanding Mechanic Levels

Mechanics can advance through various levels as they gain experience and additional certifications. Starting as an Automotive Mechanic I, individuals can progress to higher levels such as Automotive Mechanic II and III, each reflecting greater skill, experience, and responsibility. Higher levels often mean better pay and the ability to handle more complex tasks (Salary.com).

Choosing between jumping straight into work or pursuing a degree in automotive technology depends on individual circumstances, including financial situation, career goals, and personal learning preferences. Understanding the different levels of mechanics and the potential paths available can help in planning a long-term career that aligns with personal aspirations and market opportunities. For those starting out, weighing the immediate benefits of earning against the long-term advantages of education is key.

6. Potential Liability Issues

Auto mechanics face a range of potential liability issues that can arise from the nature of their work. From damages during repair work to the mishandling of a customer’s vehicle, understanding these risks is crucial for anyone in the automotive repair industry. This article outlines the common types of liabilities, preventive strategies, the importance of insurance in mitigating potential financial setbacks, and how to handle the “blame game” when customers find issues post-service.

Common Liability Risks for Mechanics

Mechanics and auto repair shops are often exposed to liability in several areas:

- Negligence: This is one of the most common legal issues mechanics face. If a mechanic fails to repair a vehicle properly, and that failure leads to an accident or further damage, the mechanic or the shop can be held liable for negligence.

- Defective Repairs: Similar to negligence, if a repair is done improperly and results in vehicle malfunction, the customer may seek damages for repairs or replacements. This can also extend to incorrect parts being used during the service.

- Property Damage: During the course of repairs, a mechanic might accidentally cause damage to the vehicle. For example, scratching the paint or cracking a windshield can lead to claims for compensation.

Each of these situations can lead to significant financial losses through direct payouts, increased insurance premiums, and damage to the business’s reputation.

Preventive Strategies to Mitigate Liability

To reduce the risk of liability, mechanics can employ several strategies:

- Thorough Documentation: Keep detailed records of all interactions with customers and their vehicles. This includes notes on specific customer requests, pre-existing damage, and detailed invoices of work performed.

- Clear Communication: Always communicate clearly and effectively with customers about what repairs are needed, why they are needed, and what they will cost. Obtain written approval before beginning any work that was not initially agreed upon.

- Regular Training: Ensure that all mechanics are up-to-date with their training and fully qualified for the tasks they are performing. This reduces the risk of mistakes due to oversight or lack of knowledge.

- Quality Control: Implement a system of checks and balances where completed work is reviewed by a senior mechanic or shop manager to ensure that it meets the required standards.

The Role of Insurance in Protecting Against Liabilities

Insurance plays a pivotal role in protecting mechanics and auto repair shops from the financial implications of liability claims. Key types of insurance include:

- General Liability Insurance: This covers injuries or property damage caused by a business’s operations. For mechanics, it can protect against claims of damage done to a vehicle while it is in their care.

- Professional Liability Insurance: Also known as errors and omissions insurance, it covers the business against claims of negligence or inadequate work.

- Garage Keepers Insurance: Specifically designed for businesses that take custody of customers’ vehicles, protecting against damages to vehicles while they are stored at the facility.

The Blame Game

It’s not uncommon for mechanics to face the “blame game,” where customers claim that something is wrong with their vehicle after a repair, alleging that the issue is related to the work that was just completed. Often, these new issues are entirely unrelated to the original repair. Handling such situations requires:

- Investigative Skills: Diagnose the issue thoroughly to determine whether it’s connected to the original repair. This may involve revisiting the vehicle’s service history.

- Customer Education: Explain to the customer how the new problem is unrelated to the work done. Clear explanations and showing diagnostic data can help in easing the customer’s concerns.

- Service Guarantees: Offering guarantees on work can provide customers with peace of mind and demonstrate the shop’s commitment to quality and accountability.

By understanding and addressing these potential liability issues, including how to manage post-service complaints effectively, mechanics can protect their professional interests while maintaining good customer relationships. This balance is key to long-term success and personal satisfaction in the demanding field of auto repair.

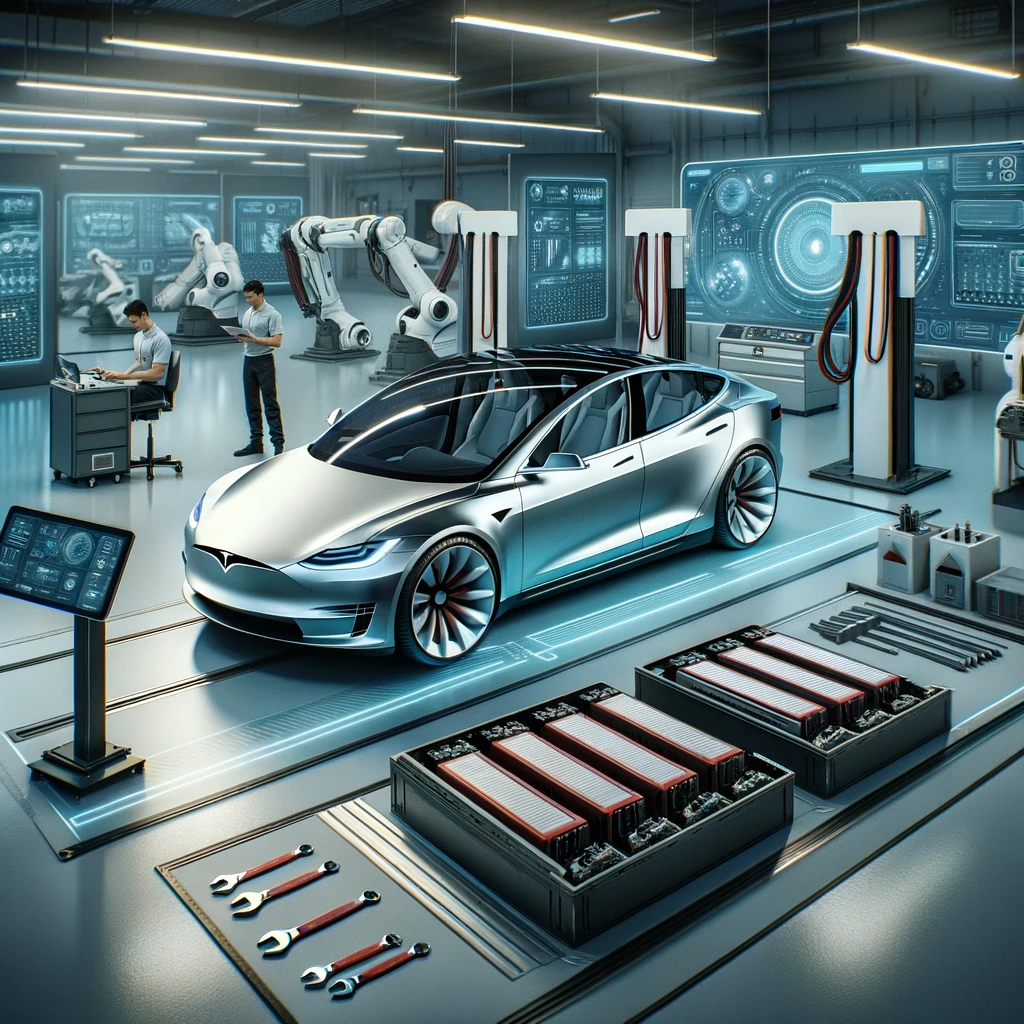

7. Job Market Trends

The automotive industry is rapidly evolving, significantly impacting the role of auto mechanics. The rise of electric vehicles (EVs), the need for specialized tools and equipment, and the requirements for specific certifications are reshaping what it means to be a mechanic today and in the future. This article breaks down these shifts into three detailed categories.

1. The Evolution of Electric Vehicles and the Future Job Market

The surge in electric vehicle adoption is one of the most transformative trends in the automotive industry. As of 2024, EVs are not just a niche market; they represent a significant portion of new vehicle sales, driven by environmental concerns and advancements in technology. For mechanics, this shift means a need to understand electric drivetrains, battery management systems, and electronic control units, all of which differ significantly from traditional internal combustion engine vehicles.

The job market for mechanics is expanding in this area, but with a twist: there is a higher demand for technicians trained specifically in electric vehicle maintenance and repair. Automotive service centers are increasingly seeking mechanics with knowledge of high-voltage systems and electronic diagnostics, anticipating the growth in EVs on the road.

2. Specialized Tools and the Cost of Keeping Up

As vehicles incorporate more advanced technology, the tools required to maintain and repair them also evolve. Modern vehicles, especially EVs and hybrids, require specialized diagnostic tools and equipment that can be costly. For example, a high-quality professional scan tool capable of detailed diagnostics across various makes and models can cost upwards of $1,500 to $3,000. Additionally, working on high-voltage systems in EVs often requires insulated gloves, specialized meters, and safety equipment designed to handle electric currents without risking electrocution.

The investment in these tools is a significant consideration for any mechanic. Shops need to keep up with technology to remain competitive, and mechanics often bear some of these costs as part of their toolkits. This need for continual investment in new technology and tools means that mechanics need to plan financially for ongoing education and tool acquisition.

3. Certifications for Modern Mechanics and Voltage Expertise

To work on electric and hybrid vehicles, mechanics must often obtain specific certifications. These certifications ensure that technicians have the skills and knowledge to safely and effectively work on vehicles with high-voltage systems. For example, the National Institute for Automotive Service Excellence (ASE) offers specific certifications for hybrid and electric vehicles, which cover the essentials of high-voltage systems, safety practices, and specific repair methods.

These certifications are crucial not only for safety but also for employment. Many dealerships and repair shops require these certifications as a condition of employment for working on newer models of electric and hybrid cars. The cost of obtaining these certifications can vary, but they are an essential investment in a mechanic’s future, often resulting in higher pay and better job opportunities.

The Future Evolution of the Mechanic Role

Comparing the past and present roles of auto mechanics, the future promises even more specialization. The mechanic’s job has transitioned from mostly mechanical repairs to a role that increasingly involves electronic diagnostics and software troubleshooting. The trend is moving towards a blend of an electrician and a computer technician role, embodying skills that span traditional mechanics and advanced IT.

As the industry continues to innovate, auto mechanics will need to remain flexible and proactive about continuous learning. The future is bright for those who adapt, offering opportunities to work on the cutting edge of automotive technology.

Conclusion

In conclusion, becoming a mechanic in 2024 involves navigating a dynamic industry with evolving technologies and customer expectations. Key considerations include the impact of electric vehicles, the necessity for specialized tools and certifications, and the challenges of managing customer relationships and liability issues. Mechanics must be prepared for ongoing education and investment in their tools and skills. This career offers rewarding opportunities for those who are adaptable, communicative, and proactive in their professional development, ensuring they stay ahead in a rapidly changing automotive landscape. By understanding these factors, aspiring mechanics can make informed decisions about their career path.

Good luck with your mechanical endeavors and feel free to check out our other articles packed with knowledge. Thank you for reading.

KC Car Products earns a commission from our sponsored links.

Contact Us At kccarproducts@gmail.com